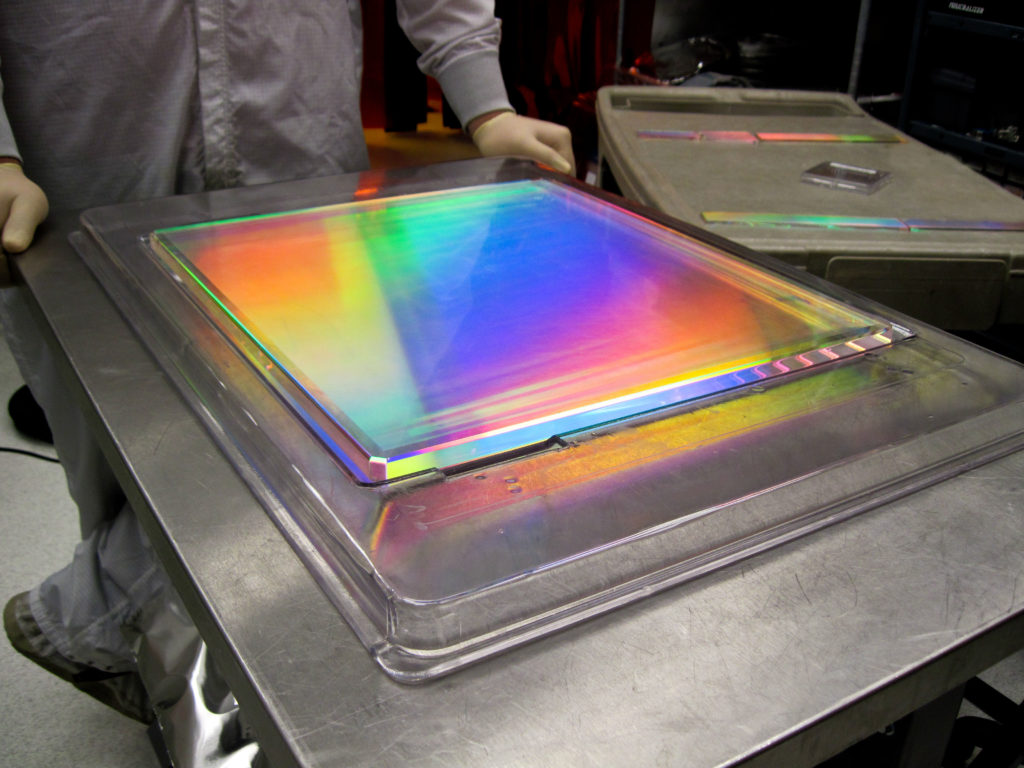

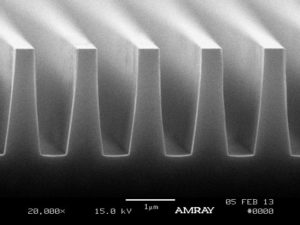

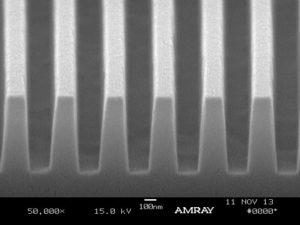

Transmission gratings require very deep groove depths to achieve high diffraction efficiency into the desired order – typically 3 – 10 times deeper than MLD and gold gratings. PGL has developed a deep etch process based on reactive ion etching (RIE) capable of attaining > 2.5 μm groove depths directly in fused silica substrates. The high uniformity of this process coupled with the precision of Scanning Beam Interference Lithography implemented in PGL’s Nanoruler grating writing technology leads to exceptional Diffracted Wavefront Error performance.

Superior antireflection (AR) coatings are also critical for transmission gratings. PGL’s experience in thin-film coating enables us to produce our own optimized AR coatings for each transmission grating design. The resulting gratings are ideal for compact, commercial systems from laser pulse compressors to spectrometers.

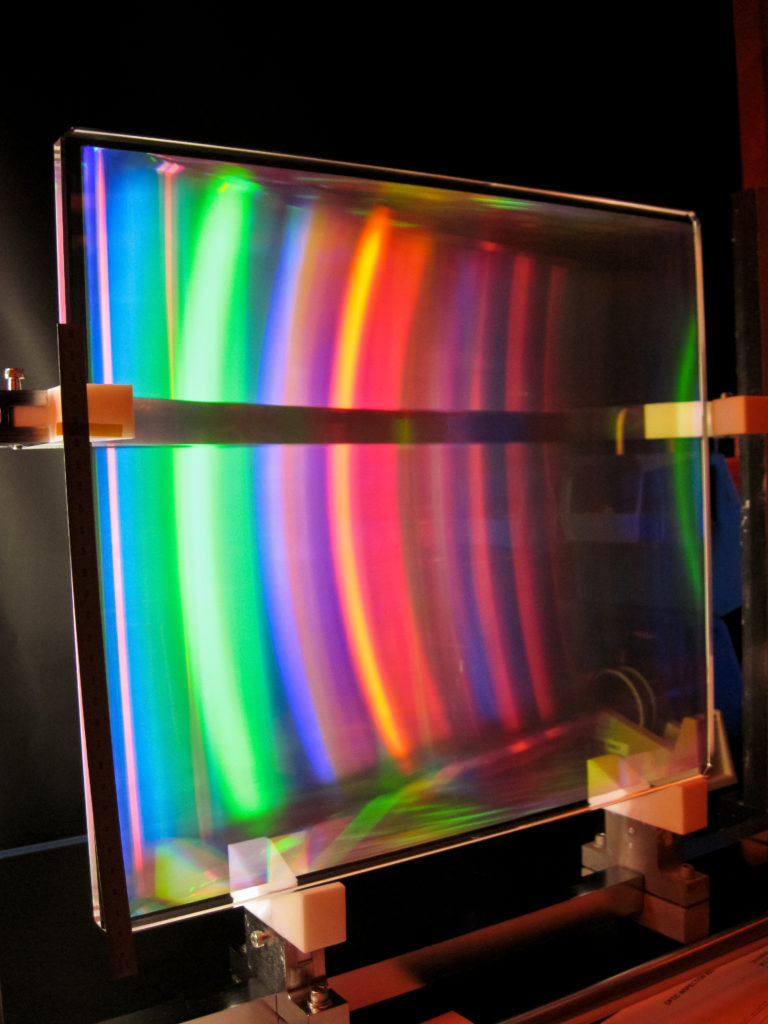

PGL’s grating exposure and etching processes produce exceptionally smooth, uniform, and deep grating grooves for negligible diffracted wavefront distortion and high uniformity and diffraction efficiency.

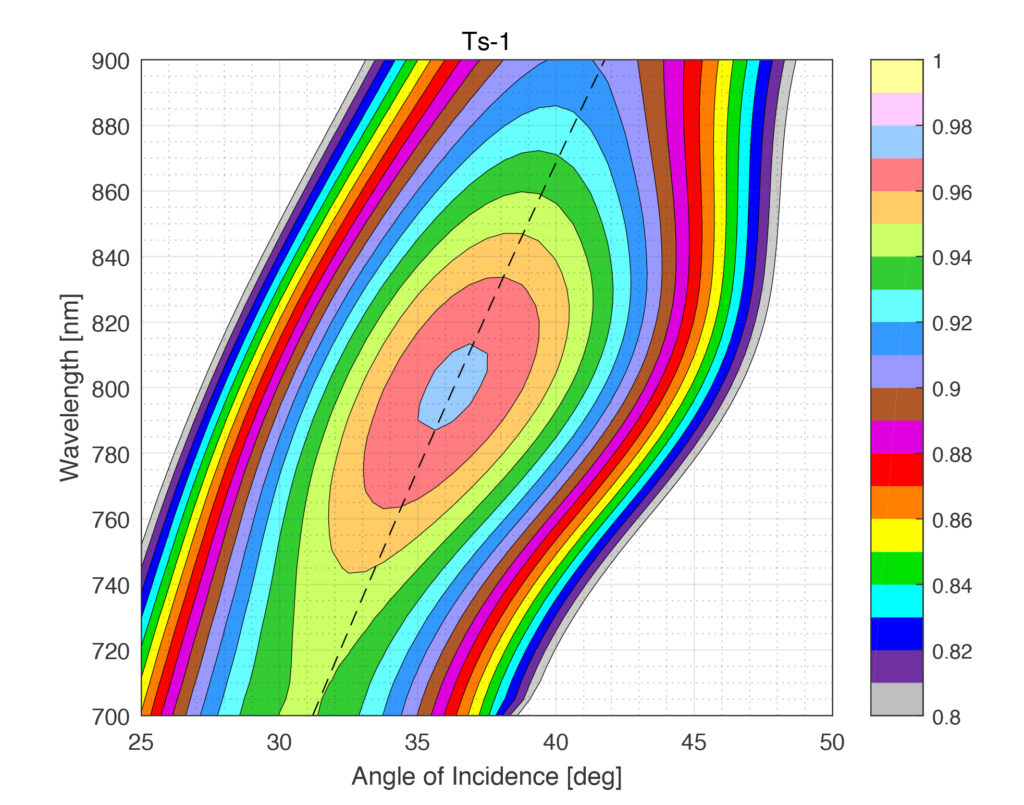

The plot below shows the theoretical diffraction efficiency vs. input wavelength and angle of incidence for a 1,200 l/mm grating optimized for 800 nm. Actual gratings typically have DE 1 – 2% below theory.

Focusing Gratings

In addition to the many advantages of PGL’s SBIL grating writing technology for standard gratings – high diffraction efficiency, consistent duty cycle, and period repeatability of 10 ppb from part-to-part – the Nanoruler also can readily produce curved grating lines. As a result, we can produce both spherically and cylindrically focusing gratings.

Applications of this new and unique capability range from simplification (reduced element count) in ultrahigh- intensity laser installations to cylindrical focusing of excimer lasers for annealing systems, to lenses for laser-based free-space communications.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com