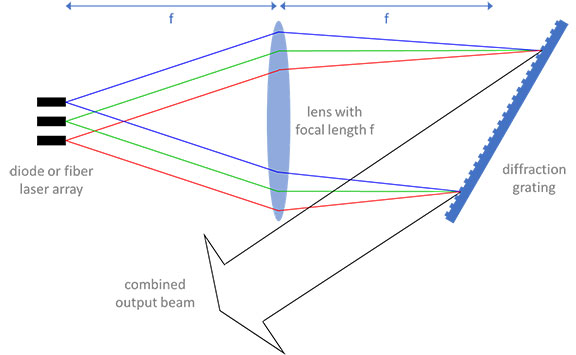

Spectral beam combining (SBC) offers an efficient and compact method to achieve extremely high cw laser powers. Many incoherent laser beams, each with a slightly different wavelength, are superimposed onto a single beam using a device with angular dispersion such as a prism or grating. The power in the resulting beam is the sum of the powers of the individual beams. Therefore this approach is said to offer a straightforward means of “power scaling.”

The individual laser beams are most often emitted by an array of fiber or diode lasers. The technique is very robust due to its mechanical simplicity, though it does require precise control of the individual wavelengths associated with the emitters. It is applicable only to systems that do not require single-frequency or at least very narrowband irradiation. If each input beam is diffraction-limited and high-performance optics are used, the combined output beam is also diffraction-limited. For this reason, along with the superior power-scaling efficiency of SBC, it is a very desirable approach to extremely high laser powers especially for compact, real-world systems.

The individual laser beams are most often emitted by an array of fiber or diode lasers. The technique is very robust due to its mechanical simplicity, though it does require precise control of the individual wavelengths associated with the emitters. It is applicable only to systems that do not require single-frequency or at least very narrowband irradiation. If each input beam is diffraction-limited and high-performance optics are used, the combined output beam is also diffraction-limited. For this reason, along with the superior power-scaling efficiency of SBC, it is a very desirable approach to extremely high laser powers especially for compact, real-world systems.

Using SBC it is now possible to use direct-diode lasers for multi-kilowatt industrial applications including cutting, welding, and other materials processes where a high-intensity laser beam is used to locally raise the temperature of the material. Until recently, such multi-kW lasers comprised only CO2, fiber, bulk solid-state, and disk lasers. Compared to these, direct-diode SBC lasers offer higher efficiency, improved reliability, graceful degradation (a single diode failure only mildly affects performance), relative lower cost, and compact size. And of course SBC offers a power-scaling upgrade path to existing materials processing fiber lasers.

SBC technology is also an ideal solution for directed-energy defense applications. Its compactness and efficiency are particularly critical for field mobile units. It can even be combined with other power-scaling methods, like coherent beam combining of fiber lasers, to achieve powers suitable for the longest-range ballistic projectile countermeasures.

Numerous other applications for SBC are under development, including long-range illumination and sensing, high-power fiber laser pumping, and fiber-delivered therapeutics.

Both multilayer dielectric (MLD) reflection gratings and all-glass transmission gratings are used for SBC. These grating types exhibit the highest possible laser-induced damage threshold (LIDT), which is critical for SBC. Maximum diffraction efficiency is also vital. For MLD gratings, it is especially important that the thin-film structure has near-unity reflectivity with exceptionally low absorption as well as optimized stress performance to minimize wavefront error at maximum power levels.

A key challenge for fiber laser based SBC systems is polarization management. Polarization-maintaining fibers add expense and complexity, and do not perform as well as standard fibers. The ideal alternative is non-polarizing gratings. These are possible but substantially more difficult to design and produce than single-polarization gratings. Nevertheless, with careful control over the manufacturing process, gratings with nearly theoretical performance can be realized today.

Find out more about PGL’s MLD gratings for Spectral Beam Combining.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com