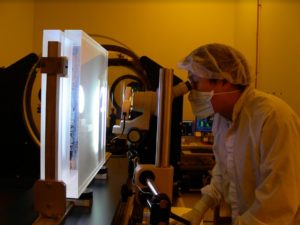

PGL has many years of experience developing cleaning processes that permit the highest laser-induced damage thresholds (LIDT). Our custom-designed cleaning equipment permits hands-free handling for most process steps.

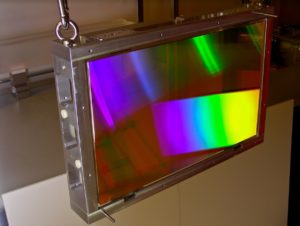

In-process tooling is carefully designed to allow thermal expansion of substrates and tooling without damage to the optics. Custom designed and tested handling tooling allows for safe handling of the substrates. Special packaging protects substrates from contamination.

PGL provides thorough analysis and documentation of any cosmetic defects at multiple stages throughout the production process.

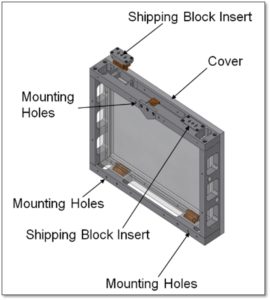

PGL’s custom-designed and manufactured bezel mounts remove uncertainty and hazards from the grating transport and mounting process. These mounts:

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com