PGL is the leading commercial supplier of gratings that are proven to meet the performance requirements of Directed Energy HEL systems. For over 15 years we have been supplying MLD gratings to the world’s premier ultrahigh-intensity laser facilities and laser manufacturers.

PGL is the leading commercial supplier of gratings that are proven to meet the performance requirements of Directed Energy HEL systems. For over 15 years we have been supplying MLD gratings to the world’s premier ultrahigh-intensity laser facilities and laser manufacturers.

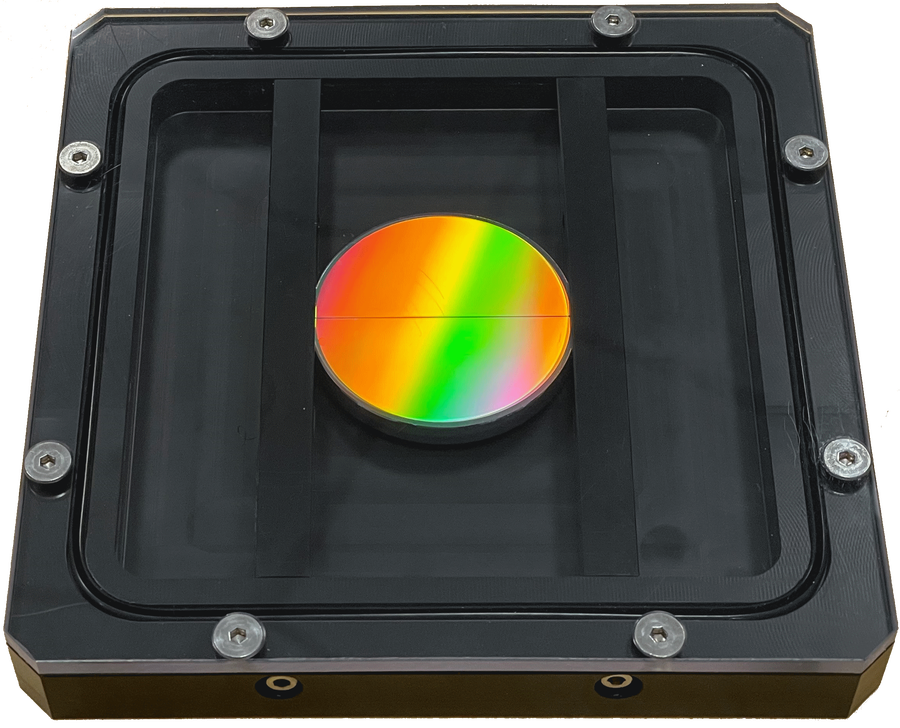

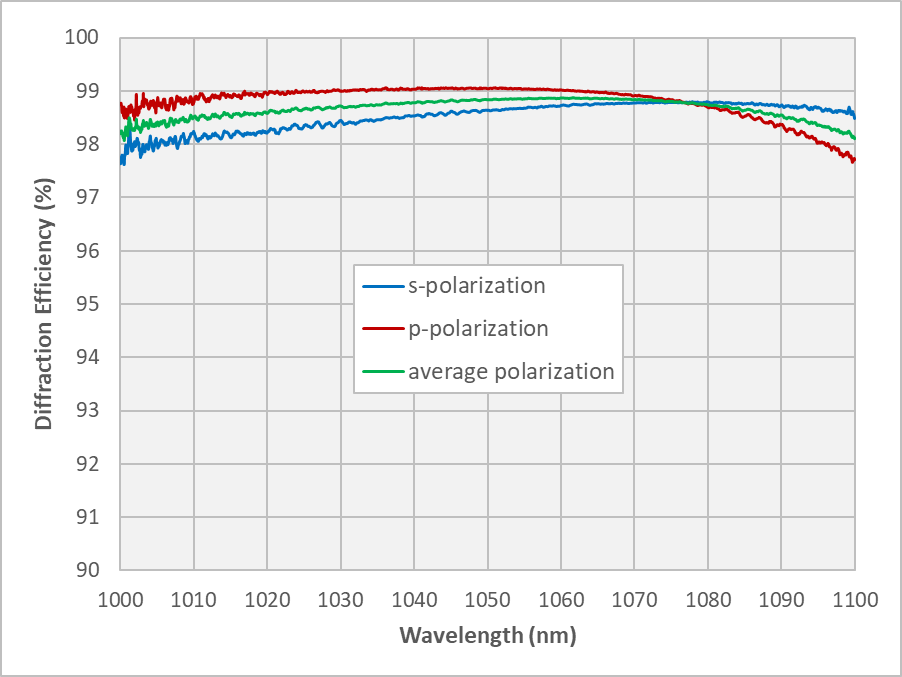

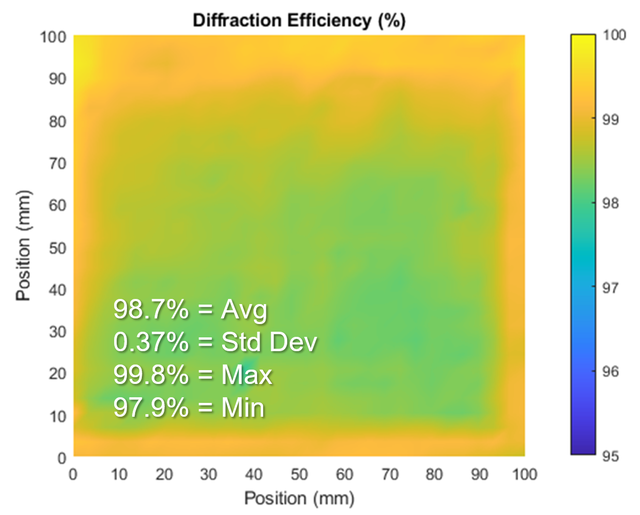

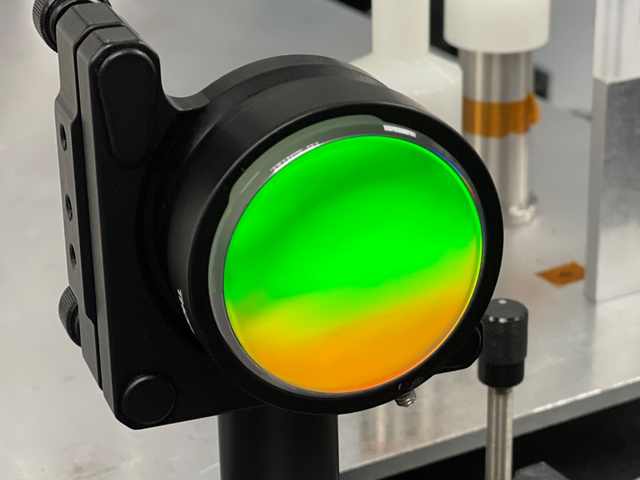

PGL’s innovative combination of thin-film coating technology with grating design and fabrication know-how allows the diffraction efficiency, wavefront, LIDT, and power-handling capability required for Spectral Beam Combining (SBC) laser systems.

PGL has extensive expertise in grating manufacturing, as well as in thin-film optical coating, reactive-ion etching, optical metrology, and precision cleaning, inspection, and handling of large optics. All these processes are critical to high-performance MLD diffraction gratings for spectral beam combining.

PGL’s unique grating designs and proprietary thin-film coating processes enable us to produce SBC gratings with the highest possible diffraction efficiency, widest spectral bandwidth, and superior manufacturability.

And we are always innovating. PGL demonstrated the first all-silica-tooth gratings on high-damage-threshold, low-loss silica-hafnia thin-film coatings. These next-generation gratings will be required to meet the needs of future HEL systems with intensities > 1 MW/cm2.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com