To transfer a photoresist grating pattern into the glass substrate, PGL utilizes a custom reactive ion beam etcher specifically designed for fine dimension control and pattern uniformity on large substrates. Up to meter-sized substrates are mounted grating side down at the top of the chamber. Etching is performed by reactive gases and a gridded radio-frequency (RF) ion source. A unique x-y scanning stage maximizes uniformity by moving the substrate through the beam during the etching process.

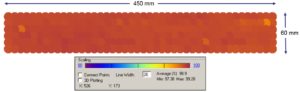

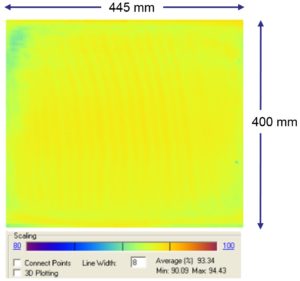

PGL has also developed a custom optical monitoring system that allows in-situ measurement of grating diffraction efficiency. Because this system utilizes the scanning x-y substrate stage, it enables not only the optimal efficiency, but also excellent uniformity especially for metal-coated gratings.

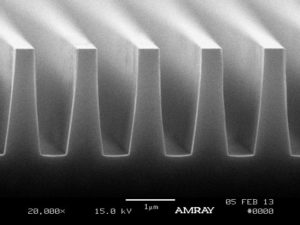

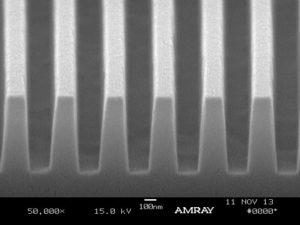

PGL has also developed an RIE process in its RF plasma reactors for very deep etching in fused silica. This process is particularly important for transmission gratings, as these require deeper grating grooves. It is capable of producing exceptionally smooth, deep, high-aspect-ratio grating grooves. Groove depths as deep as 2.5 µm are routinely produced.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com