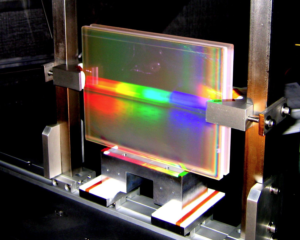

Multilayer dielectric optical films are used to achieve high laser-induced damage threshold coatings for mirrors in high energy lasers. These coatings, usually made without ion-assisted deposition (IAD), can have low stress in a typical laboratory atmosphere on any substrate material. However, some applications, such as the generation of time-compressed pulses require a vacuum environment for propagation of the laser pulse. In these applications, films on low thermal expansion substrates develop excessive tensile stress. Ion-assist using an RF ion source is used to increase the compressive stress in the multilayers to achieve a low stress, high laser damage threshold multilayer coating on a silica substrate in vacuum. These coatings are suitable for use in an alldielectric diffraction grating (MLD).

Multilayer dielectric optical films are used to achieve high laser-induced damage threshold coatings for mirrors in high energy lasers. These coatings, usually made without ion-assisted deposition (IAD), can have low stress in a typical laboratory atmosphere on any substrate material. However, some applications, such as the generation of time-compressed pulses require a vacuum environment for propagation of the laser pulse. In these applications, films on low thermal expansion substrates develop excessive tensile stress. Ion-assist using an RF ion source is used to increase the compressive stress in the multilayers to achieve a low stress, high laser damage threshold multilayer coating on a silica substrate in vacuum. These coatings are suitable for use in an alldielectric diffraction grating (MLD).

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com