Chirped Pulse Amplification (CPA) is a technique for amplifying short laser pulses to extremely high peak power level — up to 1 PetaWatt (PW) and beyond. CPA of laser pulses was first demonstrated at the University of Rochester’s Laboratory for Laser Energetics in 1985. It was invented to circumvent the limitation of optical amplifiers to withstand very high intensities of light, which effectively caps the intensity of an amplified short pulse.

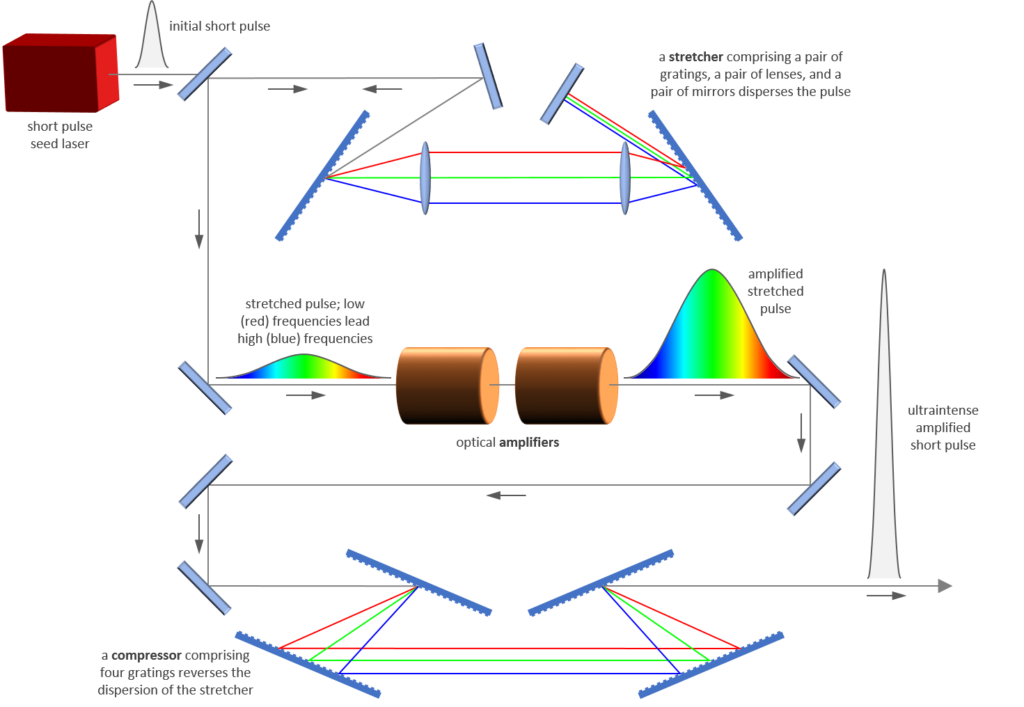

In CPA a short laser pulse is stretched in time by a factor of as high as 10,000 using dispersive optics, such as diffraction gratings, so that the peak intensity is much smaller than that of the unstretched pulse and well below a value that would cause damage in an optical amplifier. The stretched pulse is then amplified in an energized solid-state gain medium, such as titanium-doped Sapphire or neodymium-doped crystal or glass, or using optical parametric amplification in a nonlinear crystal. After amplification, the pulse is compressed using a different arrangement of gratings back to its original, short duration, but now with an extremely high peak intensity.

In CPA a short laser pulse is stretched in time by a factor of as high as 10,000 using dispersive optics, such as diffraction gratings, so that the peak intensity is much smaller than that of the unstretched pulse and well below a value that would cause damage in an optical amplifier. The stretched pulse is then amplified in an energized solid-state gain medium, such as titanium-doped Sapphire or neodymium-doped crystal or glass, or using optical parametric amplification in a nonlinear crystal. After amplification, the pulse is compressed using a different arrangement of gratings back to its original, short duration, but now with an extremely high peak intensity.

With the ultrahigh intensity pulses made possible by CPA, our understanding of light, matter, and energy have dramatically advanced. At the same time, many new applications have emerged for processing materials for both industrial and medical purposes.

From a scientific perspective, a new frontier of light-matter interactions has been opened with ultrahigh intensity laser pulses. When tightly focused, pulses with peak powers greater than 1 PW can produce intensities higher than 1021 Watts/cm2 and resulting electromagnetic fields that are much stronger than the fields that bind electrons to atomic nuclei. As a result, it has been possible to directly observe the ultrafast motions of the electrons controlling the molecules of life, the dynamics of proteins, and the motion of atoms in semiconductors. And scientists are now able to create conditions in a laboratory that mimic those found in some of the most exciting and inaccessible places in our universe, like the center of a star.

Through a process called secondary-source radiation, in which ultrahigh intensity pulses are focused on target materials whose atoms become sources of X-rays as well as accelerated electrons and protons, new applications for nondestructive imaging and evaluation of materials and structures have been developed. Accelerated proton beams produced this way may be used in cancer therapy, obviating the need to build large, expensive cyclotrons at hospitals.

Likewise numerous industrial and medical applications have been demonstrated using high intensity, ultrashort laser pulses. Unlike traditional laser materials processing, in which lasers are used to melt materials to cut, drill, weld, mark, etc., with ultrashort-pulse lasers light interacts with materials on a time scale much shorter than thermal processes can occur. As a result cuts are much more precise with less collateral damage from heat, making this type of processing ideal for high precision work and surgical applications. The primary limitation of this technology is speed, and hence commercial laser manufacturers continue to push toward higher intensities of these ultrashort pulses, demonstrating why CPA is so important for successful adoption.

Diffraction gratings are key enabling components for both stretching and compressing pulses in CPA. While other dispersive optics—such as prisms, optical fiber, and chirped mirrors—can be used in certain situations, only gratings offer the flexibility to achieve optimal dispersion over broad angular and spectral bandwidths, and the scalability to match ever-increasing beam sizes for higher intensities.

The gratings in a pulse compressor are the first optics to see an ultrahigh-intensity beam in a CPA laser system, and therefore are highly susceptible to laser damage. The gratings must be perfectly clean and have minimal defects, and must be designed to have the smallest possible electric field enhancement in the grating teeth and any thin film layers. High diffraction efficiency and minimal absorption are also required for the highest laser damage threshold. Uniformity of the efficiency and wavefront error are also critical to ensure a homogeneous beam without any “hotspots” throughout the downstream beam transport and focusing system.

For these reasons, in many CPA systems the gratings ultimately limit the maximum achievable intensity, and therefore should be designed and manufactured with great care.

5 Commerce Way, Carver, MA 02330, USA|+1.508.503.1719|sales@plymouthgrating.com